Thermographic Services

Drone Thermography Inspection Services from DroneX Industries, headquartered in Nibley, Utah, will provide you with a safer, faster and more cost-effective way of evaluating potential moisture infiltration, thermal anomalies, and energy deficiencies in your roof, building structure, or electrical system.

Our Aerial Inspection Services

DroneX Industries offers a wide range of aerial thermographic inspection services, including (but not limited to):

- Aerial Roof Inspection – Heat rises, and it costs extra money to offset heat loss due to leaks. This service is best performed in the evening after the roof has cooled from the sun’s exposure during the day. We utilize our drone to perfomr a 360° evaluation of your roof and upper building elevations, to capture where you may be losing heat. This could be due to a bad roof, poor insulation, loose singles, bad vent boots, etc. However, our inspection will provide a picture of exactly where your loss is occurring so that further investigation and repairs can be made.

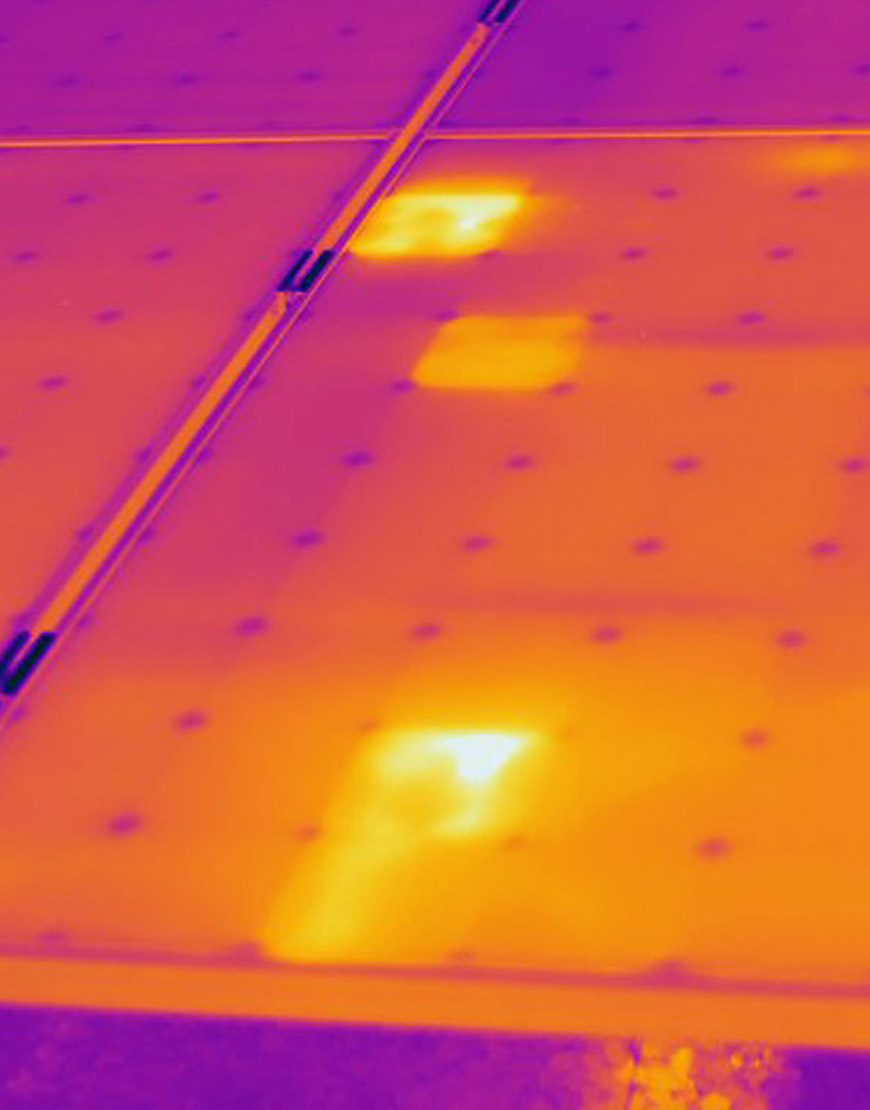

- Solar Panel Inspections – Solar panels are becoming more common every year and regular inspections are important to ensure efficient power generation, long service life, and high returns on investment. Performing aerial drone thermal inspections starting with new installation and followed by annual inspections will help extend the solar panels’ lifetime, as well as catching issues early on to ideally capture manufacturing issues for a warranty claim where applicable. Inspections are performed under normal operating conditions and do not require a shutdown.

- Electrical System Inspections – Dronex Industries provides high-resolution digital photography and inspections to help maintain, build, or modify electrical systems including but not limited to cell phone towers, wind turbines, solar farms, how power transmission lines, and other elevated structures that are difficult or impossible to reach on foot or too dangerous to inspect while in service. Our inspection typically does not require a shutdown, and our report contains complete documentation includes noting visible deficiencies, documenting the conditions at the time of inspection, and highlighting any areas of interest such a loose terminal connections or insulation wear.